Design of a cryogenic tank for liquid or cryo-compressed hydrogen for mobile applications

Activity carried out by Federico Bagnasco and Daniela Zarrilli (tutored by Laura Savoldi), in collaboration with HVM, Eng. Claudio Mascialino, Eng. Giovanni Fatigati.

Objective of the activity:

Conceptual design of a cryogenic tank for the storage of liquid and cryo-compressed hydrogen, for a heavy-duty vehicle (HD). The activity will include a functional analysis and a preliminary study of geometry, materials, mechanical and thermal characterization of the tank as well as a preliminary P&ID and some design verifications through FEA and CFD analysis.

Framework of the activity:

Currently, the transport sector is almost entirely tied to the use of fossil fuels. In fact, medium-duty and heavy-duty vehicles are the main consumers of oil in Europe and are responsible for approximately 32 % of CO2 emissions. With the growing attention to the environmental impacts and to climate and energy policies, hydrogen fits into the broader context of a multi-year strategy, with the achievement of the objectives in 2050, aimed at achieving climate neutrality. Nowadays, hydrogen is used in several industrial sectors, but the transport sector still lags behind. We will focus on the preliminary design of the tank, analyzing two innovative storage techniques.

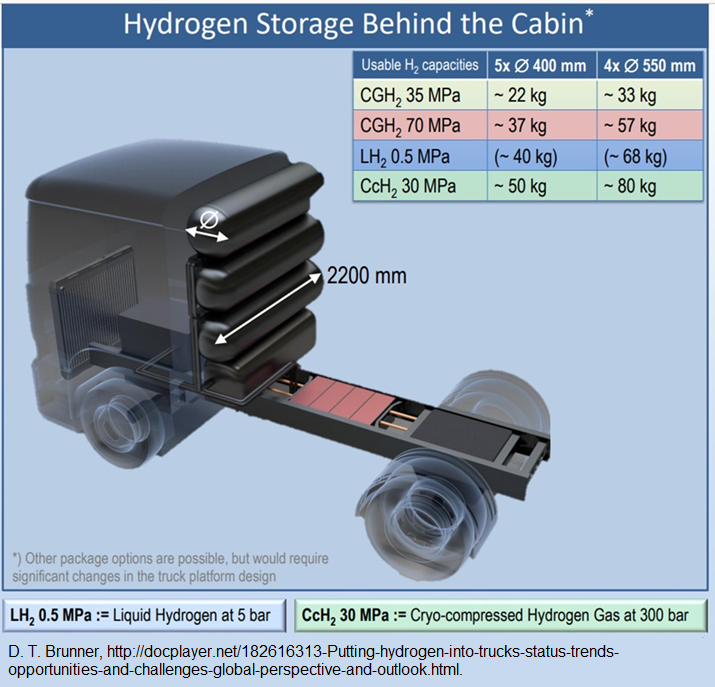

Figure 1. Vehicle storage system.

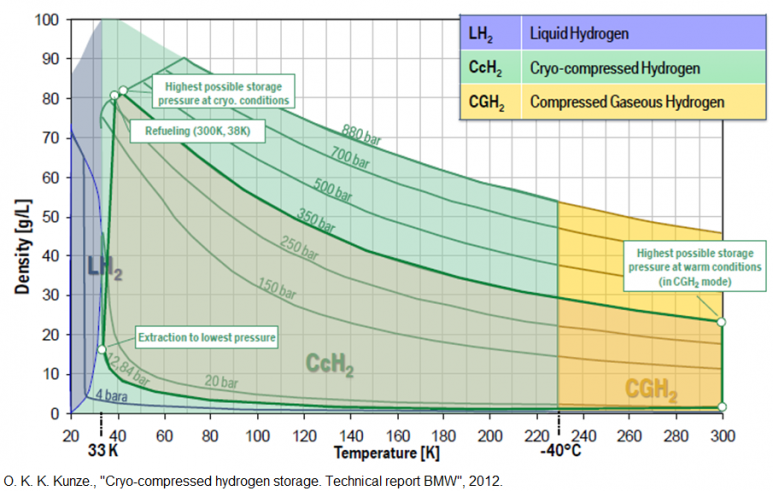

Currently, in the automotive sector, hydrogen is stored as gas, contained in pressurized tanks at 350-700 bar. However, this may not be the best technique. In fact, as can be seen in the diagram, the gaseous storage allows to reach relatively low-density values. As initial hypothesis, this means that to obtain comparable performance of vehicles, such as autonomy, speed and fuel consumption, tanks must be heavier and bulkier with a reduction of available load.

Figure 2. Storage techniques and operation values.

Therefore, cryogenic storage of hydrogen is adopeted; thus, densities of 65 g/L for liquid hydrogen and 80 g/L for cryo-compressed hydrogen are reached. Both techniques involve the use of cryogenic tanks, that are formed by two shells separated by a gap in which Multi-Layer Vacuum Super insulation is realized. The main differences between the two methods are:

- Storage conditions;

- Materials used for the internal tank;

- Sensitivity to heat exchange.

At a temperature of -253 °C and a pressure of 1 bar, hydrogen is liquid; in this form it is highly sensitive to heat exchange, so a careful design of the insulation system must be carried out. While cryo-compressed hydrogen is gaseous, and it is contained in a pressurized tank at 300 bar and at a temperature of -235 °C. The slightly higher temperature makes it less sensitive to incoming heat from the outside, but the design of the tank must be conducted to ensure the structural safety of the system.