Critical raw materials

Critical raw materials (CRMs) are becoming increasingly important in the current energy debate. Clean energy technologies necessary for the energy transition require many raw materials whose supply chain is typically highly geographically concentrated and/or politically unstable [1]. This might increase the probability of supply disruption with potentially relevant impacts for the national economies worldwide [2]. In this regard, energy system planning should include CRMs supply chains in their modelling to provide more comprehensive insights to policymakers concerning potential supply disruption [3]. However, most of the current literature applies ex-post material intensity (MI) and supply risk (SR) indicators to preexisting energy scenarios: this implies that the results of ESOMs are not directly influenced by supply chain risks, leading to potentially to unfeasible or incomplete results [4]. To overcome this research gap, we integrated CRMs in TEMOA as described below.

Modeling the CRMs value chain

The value chain of CRMs was integrated in the TEMOA version that also includes the MOO module [5]. Then, the value chain of selected materials from the CRMs list of the European Commission published in 2023 was included in a novel version of the TEMOA-Italy instance [6]. The novelties compared to the traditional MAHTEP version of TEMOA [7] are: a new commodity type modeling the single CRM, which can be provided in the energy system by generic supply process; three equations modeling consumption, balance, and maximum availability of the CRM; a variable and a parameter to track the consumption of the CRM and a parameter to set a maximum material availability.

The consumption of material is evaluated by technology and occurs when the technology is installed. It is computed by multiplying the newly installed capacity by a new parameter measuring the material intensity. The latter is a specific material consumption defined in unit mass of the material per unit capacity of the technology requiring the material). Then, as for the energy commodities, the material commodities are subject to a balance constraint to ensure a system level balance. Finally, a maximum availability constraint is applied to the materials supply processes to set the maximum value that can be reached over the entire model time horizon. For more details about the actual implementation in TEMOA, see [4], [8], [9].

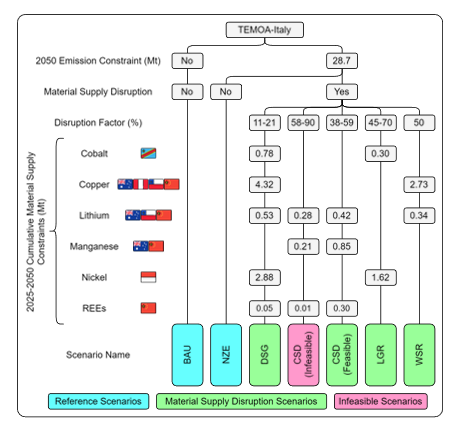

Limiting the maximum availability of materials supply allowed us to model different materials supply disruption scenarios. The latter included hypothesis on the possible causes of shortages in the materials supply chain and were used to investigating the effects on the Italian energy system in [9]. In particular, the reference materials demand of the system was evaluated from the materials consumption in the Net Zero Emission (NZE) scenario, which prescribes carbon neutrality in 2050. As discussed in [8], the materials supply disruption scenarios were defined by applying different disruption factors to the reference materials demand. The disruption factors are derived from geo-political considerations and are clearly represented in Figure 1, showing also the main suppliers (mining and processing) of the materials under constraints.

Figure 1. Graphical representation of the materials supply disruption scenarios.

The Demand-Supply Gap (DSG) scenario encompassed the wider set of materials, considering that a relevant increase in the materials demand which is not fulfilled by an adequate increase in the materials production. Instead, Chinese Supply Disruption (CSD) and the Low Governance Region (LGR) scenarios assumed the complete interruption of materials supply from China and political unstable regions, respectively. Finally, the Water Stress Region (WSR) scenario investigated the threats due to climate changes on the materials supply chain. In these scenarios the power sector presents similar compositions of the technology mix because of the need for decarbonization of the energy system. On the other hand, the transport sector is more sensitive to the constraints on the materials supply. Indeed, the shortage of materials such as lithium, cobalt and REEs, that are strongly consumed in electric vehicles, leads to a relevant penetration of alternative technologies like full-hybrid vehicles and fuel cell vehicles.

Modeling the CRMs supply risk

The SR of CRMs is defined as the probability of a supply disruption [10]. In order to account for the material SR in TEMOA, a composite and comprehensive indicator measuring the SR of energy technologies was developed based on established literature. Its definition is extensively described in [4]. In particular, the SR of a technology was defined by aggregating the SR of the single raw materials and by weighting them for the corresponding material intensity (the same used to compute the material consumption by technology in the material value chain). The SR of single raw material is in turn a composite indicator that accounts for different SR factors, such as geological, geopolitical, economic, technical, social, and environmental factors.

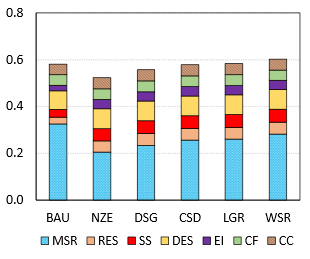

Two approaches were used to integrate the technology SR indicator in TEMOA. In the first approach, the indicator was included in a more comprehensive energy security metric, which was applied to energy scenarios derived from TEMOA-Italy, as presented in [9], [11]. The energy security metric also encompassed indicators of energy supply risk and internal reliability. The energy supply risk dimension accounted for the risks associated with the Diversification of Energy Supply (DES), the amount of Renewable Energy Supply (RES) and the Self Sufficiency (SS) of the system. On the other hand, the internal reliability of the energy system considered the end-users energy efficiency, evaluated through the Energy Intensity (EI) of the system, and the continuity and adequacy of electricity generation mix, which were expressed by the Capacity Factor (CF) and Capacity Credit (CC), respectively. In this regard, the contribution of the different indicators to the average level of energy security in the different energy scenarios is reported in Figure 2.

Figure 2. Average level of energy security (from 2025 to 2050) and the contribution of the single indicators.

The second approach provided for the minimization of the technology material SR alongside an energy SR indicator using the TEMOA version with the MOO module [5]. This approach was extensively presented in [4]. The energy SR indicator was derived based on established literature and consistently with the technology material SR indicator. The material and energy SR indicators were included in the TEMOA framework as new parameters linked to energy technologies and commodities, respectively. Then, two SR objective functions were defined by linking the SR indicators to suitable decision variables. Finally, the MOO was applied to minimize the material and energy SRs associated with the decarbonization of the Italian power sector by 2050.

Exploring near-optimal solutions with MGA

This activity focuses on energy system optimization under geopolitical risks and critical raw material supply constraints utilizing the Modeling to Generate Alternatives (MGA) methodology. We explore cost-optimal transition pathways for energy systems that enhance resilience and security.

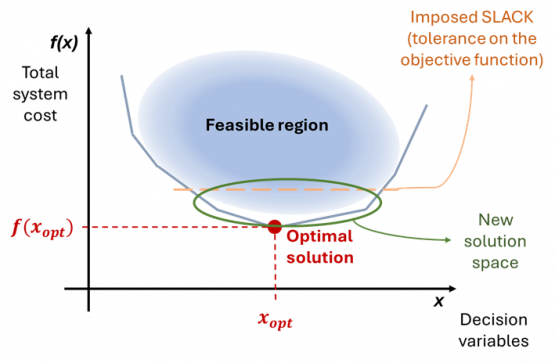

The MGA methodology allows the generation of multiple near cost-optimal solutions rather than a single optimal pathway, as shown in Figure 3. This approach helps reveal a spectrum of possible energy system configurations, highlighting trade-offs between technologies and sectors [12]. By exploring these alternatives, this research accounts for uncertainties and provides flexible solutions that can adapt to supply disruptions and geopolitical instabilities [13].

This work analyzes key sectors such as power, storage, hydrogen, and transport, with a specific focus on Italy. By examining trade-offs and interdependencies between technologies under material supply limitations, the research identifies diverse energy system configurations that meet decarbonization targets while mitigating supply chain disruptions. This research provides valuable insights for policymakers, industry stakeholders, and researchers, offering innovative solutions to ensure a stable and sustainable energy transition despite geopolitical uncertainties.

Figure 3. Modeling to generate alternatives (MGA).

References

- European Commission, “Study on the critical raw materials for the EU 2023 : final report.,” 2023. doi: 10.2873/725585.

- S. Carrara et al., “Supply chain analysis and material demand forecast in strategic technologies and sectors in the EU – A foresight study,” Publications Office of the European Union, Luxembourg, 2023. doi: 10.2760/386650.

- D. Süsser et al., “Why energy models should integrate social and environmental factors: Assessing user needs, omission impacts, and real-word accuracy in the European Union,” Energy Res Soc Sci, 2022, doi: 10.1016/j.erss.2022.102775.

- G. Colucci, J. Finke, V. Bertsch, V. Di Cosmo, and L. Savoldi, “Combined assessment of material and energy supply risks of the energy transition: a multi-objective energy system optimization approach,” Submitted to Applied Energy, 2024.

- MAHTEP Group, “MAHTEP/TEMOA/moo - Release 1.0,” GitHub. Accessed: Jun. 19, 2024. [Online]. Available: https://github.com/MAHTEP/TEMOA/releases/tag/moo1.0

- MAHTEP Group, “MAHTEP/TEMOA-Italy,” GitHub. Accessed: May 11, 2022. [Online]. Available: https://github.com/MAHTEP/TEMOA-Italy

- MAHTEP Group, “MAHTEP/TEMOA,” GitHub. Accessed: Oct. 28, 2023. [Online]. Available: https://github.com/MAHTEP/TEMOA

- A. Vai, “How may the availability of critical raw materials affect the deployment of material-intensive technologies and the security of energy systems?,” Politecnico di Torino, Turin, 2024. Accessed: Aug. 13, 2024. [Online]. Available: https://webthesis.biblio.polito.it/31959/

- A. Vai, G. Colucci, M. Nicoli, and L. Savoldi, “May the availability of critical raw materials affect the security of energy systems? An analysis for risk-aware energy planning with TEMOA-Italy,” Mater Today Energy, vol. 48, no. 101805, 2025, doi: 10.1016/j.mtener.2025.101805.

- D. Schrijvers et al., “A review of methods and data to determine raw material criticality,” Resour Conserv Recycl, vol. 155, p. 104617, Apr. 2020, doi: 10.1016/J.RESCONREC.2019.104617.

- A. Vai, G. Colucci, M. Nicoli, and L. Savoldi, “A Comprehensive Metric to Assess the Security of Future Energy Systems Through Energy System Optimization Models,” Energy Proceedings, vol. 47, 2024, doi: 10.46855/energy-proceedings-11292.

- J. F. DeCarolis, “Using modeling to generate alternatives (MGA) to expand our thinking on energy futures,” Energy Econ, vol. 33, no. 2, pp. 145–152, Mar. 2011, doi: 10.1016/J.ENECO.2010.05.002.

- A. Sinha et al., “Diverse decarbonization pathways under near cost-optimal futures,” vol. 15, no. 1, pp. 1–15, 2024, doi: 10.1038/s41467-024-52433-z.